Today is UN World Environment Day, a day for global citizens to increase awareness of and take action on the environmental issues facing us all. The 2019 theme is to beat air pollution, and in light of recent climate change protests, it seems that the need for cleaner alternatives to refining and burning fossil fuels has never been more keenly felt.

No carbon left behind

A bio-based economy, that harnesses biotechnology and renewable raw materials to create fuels, chemicals and materials, aims to reduce both the consumption of fossilized carbon and the resulting pollution.

I recently attended the Symposium on Biotechnology for Fuels and Chemicals, where the keynote speaker, Jennifer Holmgren (CEO of Lanzatech) set the tone of the meeting with a proposal that we should limit our fossil-based carbon budget to the essentials, and that energy can be carbon free. Her company has commercialized microbiological systems to make fuel ethanol and bio-based chemical products from industrial carbon waste streams (e.g. steel mill emissions, which would otherwise be released to the atmosphere). Jennifer’s ideology to conserve and recycle industrial carbon is neatly captured in her motto “no carbon left behind”.

I recently attended the Symposium on Biotechnology for Fuels and Chemicals, where the keynote speaker, Jennifer Holmgren (CEO of Lanzatech) set the tone of the meeting with a proposal that we should limit our fossil-based carbon budget to the essentials, and that energy can be carbon free. Her company has commercialized microbiological systems to make fuel ethanol and bio-based chemical products from industrial carbon waste streams (e.g. steel mill emissions, which would otherwise be released to the atmosphere). Jennifer’s ideology to conserve and recycle industrial carbon is neatly captured in her motto “no carbon left behind”.

The meeting drew together researchers working to the common aim of converting renewable carbon sources (such as biomass and captured carbon) to fuels and chemicals. This year there was a growing focus on creating novel materials such as bioplastics, which are also in demand for environmental reasons.

Research published in Biotechnology for Biofuels shares the above aims and recent highlights in the journal include the discovery of novel fungal enzymes that help breakdown biomass for bio-refining as well as the engineering of a strain of Corynebacterium glutamicum that can produce bio-gasoline, whilst tolerating harsh industrial processing. A natural mutation in maize, that makes it less recalcitrant to ethanol fermentation, has also attracted considerable interest.

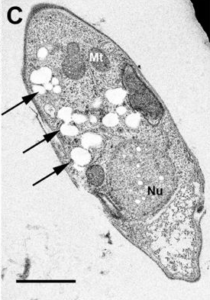

Micro-organisms are increasingly being metabolically engineered to produce biodegradable plastics. As long ago as 2011, a study in Microbial Cell Factories showed how algae could be induced to make granules of polyester within the cell (see image). More recent work in the journal shows how bioplastic precursors can also be produced in yeast and bacteria.

Currently, most bio-product innovation remains at the laboratory scale. Due to the relatively low cost of crude oil, investors see little reason to commercialize fossil fuel alternatives that will cost more to produce. The new technologies and biobased products that do get to market tend to be non-fuel products that are of high market value, however, the demand and price of these is not guaranteed. One strategy to overcome this, described by Holmgren, is to make the bio-refinery flexible in terms of its product. A production line can be swapped out (whilst using the same basic infra-structure) to make more profitable bioproducts, depending on the current market value.

On World Environment Day, we can reflect that there is an escalating social consciousness of the cost of fossil carbon and its associated waste. The solutions are already here, and we need more political and economic incentives to help us use them.

- Biotechnology for a bio-based economy - 5th June 2019

- Sustainable energy at the American Chemical Society Spring meeting - 11th April 2018

- Biotechnology for Biofuels – Special Issue on Life Cycle Analysis - 17th May 2017

Comments